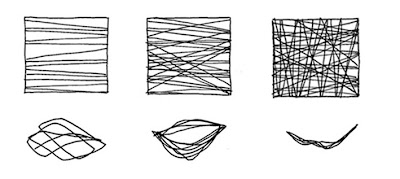

Change of surface porosity due to deformation.

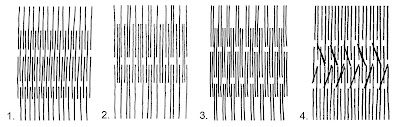

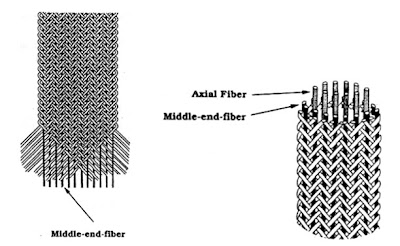

Phases of geometrical disposition of threads in single-layer woven structures by Novikov.

The decrease in the crimp height of warp thread (hwp) is equal to increase in the crimp height of weft thread (hwft). With equal diameters dwp=dwft of warp and weft threads, the crimp height of the warp thread hwp increases by 0.5 r, and the crimp height of the weft thread hwft decreases by the same value.

Thus, it is observed that dwp+dwft=hwp+hwft=4r.

Source: Elena Chepelyuk, Valeriy Choogin, Jenny Cousens, Michael Hann, (2010) "Geometric disposition of threads in single-layer woven structures", International Journal of Clothing Science and Technology, Vol. 22 Iss: 1, pp.35 - 48

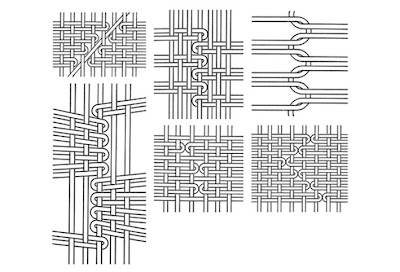

Physical Prototypes

In order to examine the structural behaviour of woven textiles physical specimens will be tested under tension and shear stress. For that reason 4 pairs of specimens were created with different patterns. Each pair consists of one unstiffened and another stiffened prototype. Thermoset resin and a hardener were used to stiff the prototypes.

The aim of the experiment is to define the deformation of each specimen and examine the differences between them. The deformation diagram will be useful in order to specify the parameter of distance between the threads in order to create a structural skin that can take the load.

Geometrical disposition of physical prototypes - Diagrams.